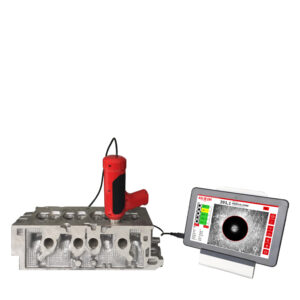

Automatic portable Brinell hardness measuring microscope for indentation reading in the field, on site and in the lab.

The ATI BR Brinell hardness measuring scope / microscope is a compact, portable digital microscope specifically engineered for accurate Brinell hardness measurement on-site environments or in laboratory. Small enough to fit in a pocket yet extremely powerful, this digital Brinell microscope is supplied with a rugged tablet running dedicated measurement software for the automatic analysis of Brinell and Vickers indentations. The system is fully compliant with ISO 6506, ISO 6507, ASTM E10, and ASTM E92 standards for hardness testing.

The fully automated Brinell hardness measuring process includes automatic brightness and contrast optimization, ensuring fast, repeatable, and operator-independent results.

Measurable Hardness Test Scales

| Brinell Hardness Scales HBW: | 1/1, 1/1.25, 1/2.5, 1/5, 1/10, 1/30 2.5/6.25, 2.5/15.62, 2.5/31.25, 2.5/62.5, 2.5/187.5 5/25, 5/31.25, 5/62.5, 5/125, 5/250 |

| Vickers Hardness Scales (Optional): | HV3, HV5, HV10, HV20, HV30, HV50, HV100 |

Measurable materials and applications

| Brinell Hardness Scales – HBW (Optical Measurement) |

Used for materials with coarse or heterogeneous microstructures where a larger indentation provides representative hardness values. Typical materials: cast iron, aluminum alloys, copper alloys, brass, bronze, non-ferrous metals. Typical applications: foundry products, large machined parts, raw materials inspection, metallurgical laboratories. |

| HB30 – Brinell Hardness Test | Designed for medium-soft metals requiring moderate test forces and good indentation visibility. Typical materials: carbon steel, mild steel, quenched and tempered steel, iron, cast iron, hard non-ferrous metals and alloys. Typical applications: general manufacturing, forged parts, castings, bars, incoming material inspection, production quality control. |

| HB10 – Brinell Hardness Test | Suitable for soft metals and light alloys, where lower test forces prevent excessive deformation. Typical materials: aluminum and aluminum alloys, copper, brass, bronze, soft steels, non-ferrous metals. Typical applications: light alloy components, extrusions, thin sections, non-ferrous parts, laboratory and production testing. |

| HB5/HB2.5/HB1 – Brinell Hardness Test | Intended for very soft materials or thin components, using low test forces for controlled indentation. Typical materials: soft aluminum alloys, copper, lead-based alloys, tin alloys, soft non-ferrous metals. Typical applications: thin parts, soft materials, research and laboratory testing, quality control of delicate components. |

| Vickers Hardness Scales | Suitable for a wide range of materials, from very soft to very hard, including small parts and thin sections when used with low test forces. Typical materials: hardened steel, stainless steel, non-ferrous metals, hard alloys, coatings, technical materials. Typical applications: laboratory testing, research and development, thin sections, small components, coating evaluation, failure analysis. |

Mechanical & Technical Specifications:

| Hardness Standards: | ISO 6506, ISO 6507, ASTM E10, and ASTM E92 |

| Objective: | 20x |

| Camera: | High resolution |

| Reading: | Automatic and manual |

| Focus: | Fixed – Auto |

| PC OS: | Windows 11 |

| Power Supply: | USB |

📏 HOW TO MEASURE THE BRINELL INDENTATION?

Thanks to its intuitive user interface, the ATI BR Brinell Microscope can be operated by users with any level of experience:

- Simply select the desired hardness scale and place the device on the sample surface

- Locate the indentation through the tablet screen

- Click the probe button and get the result immediately

The Brinell hardness measuring microscope automatically delivers the test result, optimizing productivity and inspection efficiency. Brinell and Vickers hardness testing can be performed directly on the production field, eliminating the need to move or re-position components. Designed for parts of any shape, size, or geometry, the ATI BR provides maximum flexibility with no testing limitations, making it ideal for in-process and final inspection.

🧠 SMART BRINELL HARDNESS MEASURING SOFTWARE

- Fully Automated Measurement Software: Complete automatic control of the Brinell hardness measuring microscope with additional manual reading possibility.

- Intuitive Touchscreen Interface: User-friendly touch software designed for fast, efficient operation in industrial production environments.

- Quick Test Selection: Rapid selection of Brinell or Vickers hardness scales with precise adjustment of measurement parameters.

- Advanced Data Analysis: Real-time statistics and graphical results for instant evaluation and continuous quality control.

- Smart Data Management: Save, recall, and compare test sessions for full traceability and long-term analysis.

- Automatic Image Optimization: Automatic brightness and contrast adjustment for reliable readings in any lighting condition.

- Intelligent Indentation Recognition: Advanced image recognition accurately detects indentations on rough, dirty, or uneven surfaces, filtering out debris and surface imperfections.

- High Accuracy in Harsh Conditions: Consistent, precise hardness measurements even in challenging industrial environments.

❓ FREQUENTLY ASKED QUESTIONS – ATI BR Brinell Hardness Measuring Scope / Microscope

Yes. The ATI BR Brinell hardness measuring microscope can be used on a wide range of metallic materials, including steel, cast iron, aluminum alloys, copper alloys, and other metals commonly tested with Brinell and Vickers methods.

Yes. As required by Brinell and Vickers testing standards, the surface must be properly prepared.

Surface milling or grinding is strongly recommended, especially after heat treatment, to remove scale, oxidation, or surface irregularities and ensure accurate and repeatable Brinell hardness measurements.

Yes. ATI BR is designed for on-site and production-line hardness testing, allowing measurements directly on large, heavy, or fixed components without moving them.

Yes. The probe and software can be supplied without the tablet. However, the customer’s tablet or PC must meet minimum system requirements, including:

- Windows 11 operating system

- Intel® Core™ i5 CPU, equivalent or higher

This ensures full software functionality, performance, and measurement reliability.

Yes. The system features an intuitive touchscreen interface and fully automated measurement process, making it suitable for operators of any experience level with minimal training.

Once the indentation is selected, the Brinell hardness result is displayed in a blink of an eye, ensuring fast inspection cycles and high productivity.

Yes. The software automatically adjusts brightness and contrast and uses advanced image recognition algorithms to accurately detect indentations, even on rough, dirty, or uneven surfaces.

ATI BR is supplied with a 12-month warranty covering manufacturing defects on parts, in accordance with standard industrial warranty conditions.

Yes. Spare parts are readily available, and shipments are handled immediately to minimize downtime.

Yes. ATI provides fast repair services using original spare parts to ensure long-term performance and reliability of the Brinell hardness measuring microscope.

Yes. Remote technical assistance is available for:

- Operator training

- Software configuration

- Troubleshooting and diagnostics

This allows rapid support without the need for on-site visits.

Yes. The system complies with ISO 6506, ISO 6507, ASTM E10, and ASTM E92, ensuring traceable and standardized hardness measurements.

Yes. Measurement data and images can be exported in JPG, BMP, PDF, Excel, TXT, and CSV formats for reporting, archiving, and quality documentation.