Rockwell Hardness Tester – ATI RS

The ATI RS hardness tester is a modern, digital bench hardness tester designed for precise Rockwell and Superficial Rockwell hardness measurements. Engineered for industrial and laboratory use, it delivers high accuracy, repeatability, and long-term reliability.

Automatic Rockwell Hardness Tester conform to ASTM and ISO Testing Standards

ATI RS is an automatic Rockwell hardness tester fully compliant with ASTM and ISO standards. In addition to Rockwell and Superficial Rockwell scales, the instrument can also perform Brinell and Vickers hardness testing using the depth measurement method or an external optical microscope.

The system is equipped with a high-precision load cell and a closed-loop electronic control system with a 1 kHz sampling rate, ensuring accurate force application and stable measurements over time. This technology guarantees consistent hardness test results regardless of operating conditions.

Fully Automatic Hardness Testing Cycle

The hardness test procedure is fully automated. The operator simply presses the START button:

- Automatic application of the preliminary test force

- Automatic application of the main test force

- Controlled dwell time and automatic release of the main force

- Final hardness value measured under recovery force

The measured hardness value is displayed clearly on the screen, highlighted in green or red according to the programmed tolerance limits, enabling immediate pass/fail evaluation.

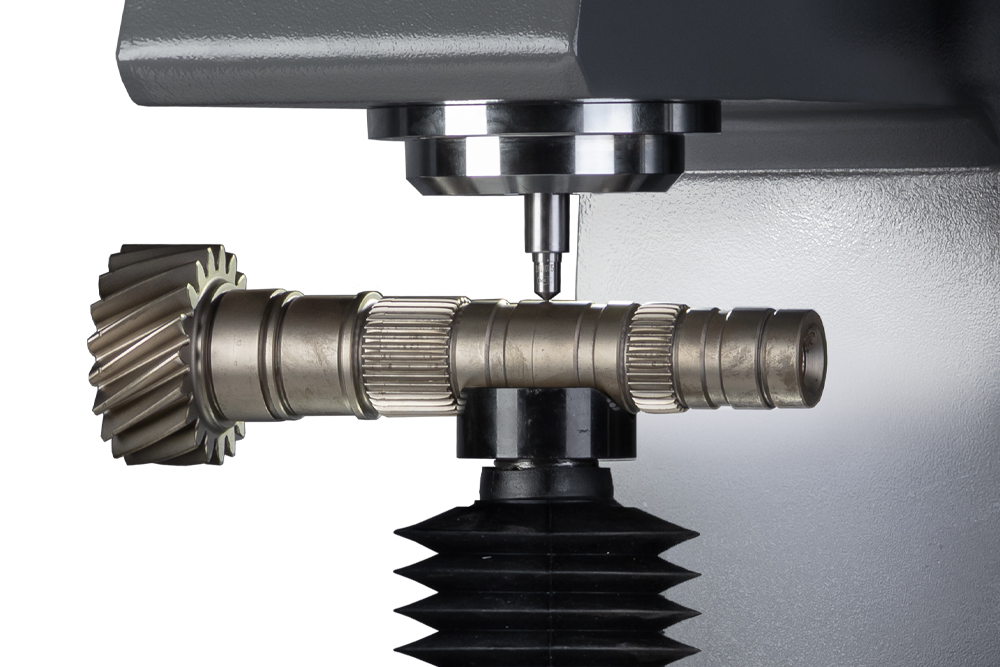

Versatile Hardness Tester for Metals and Advanced Materials

The ATI RS hardness tester is designed to accurately measure the hardness of:

- Ferrous metals: Carbon steel, alloy steel, stainless steel, tool steel, cast iron

- Non-ferrous metals: Copper, aluminum, brass, bronze, nickel alloys, light alloys

- Selected non-metal materials: Hard plastics, technical polymers, composites, resin-based materials

This makes it ideal for manufacturing, quality control, R&D laboratories, and production environments where precise and repeatable hardness testing is critical.

Available Hardness Test Scales

| Rockwell Hardness Scales: | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV |

| Superficial Rockwell Hardness Scales (15–30–45): | HRN, HRT, W, X, Y |

| Brinell Hardness Scales HBW (Optional): | 1/1, 1/1.25, 1/2.5, 1/5, 1/10, 1/30 2.5/6.25, 2.5/15.62, 2.5/31.25, 2.5/62.5, 2.5/187.5 5/25, 5/31.25, 5/62.5, 5/125, 5/250 |

| Brinell Hardness Scales – Depth Measurement HBWT (Optional): | 2.5/62.5, 2.5/187.5, 5/250 |

| Vickers Hardness Scales (Optional): | HV1, HV2, HV3, HV5, HV10, HV20, HV30, HV50, HV100 |

Mechanical & Technical Specifications:

| Maximum Workpiece Height: | 270 mm |

| Throat Depth (Column to Indenter): | 210 mm |

| Dimensions (L x W x H): | 475 x 200 x 700 mm |

| Weight: | 70 kg |

| Power Supply: | AC 110V, 220V ±5%, 50~60Hz |

| Dwell Time: | Adjustable from 2 to 60 seconds |