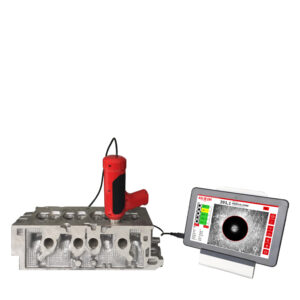

Portable Rockwell hardness tester with magnetic clamping system for any kind of sample surface

ATI MAG is a portable device specifically developed for Rockwell hardness testing, fully compliant with ASTM E18and ISO 6508 standards.

Equipped with a magnetic clamping base, it guarantees secure and stable positioning throughout the entire test cycle, ensuring constant contact with the sample surface. The measurement process is fully automated, and accurate results are delivered from the very first test, with no need for recalibration or adjustment.

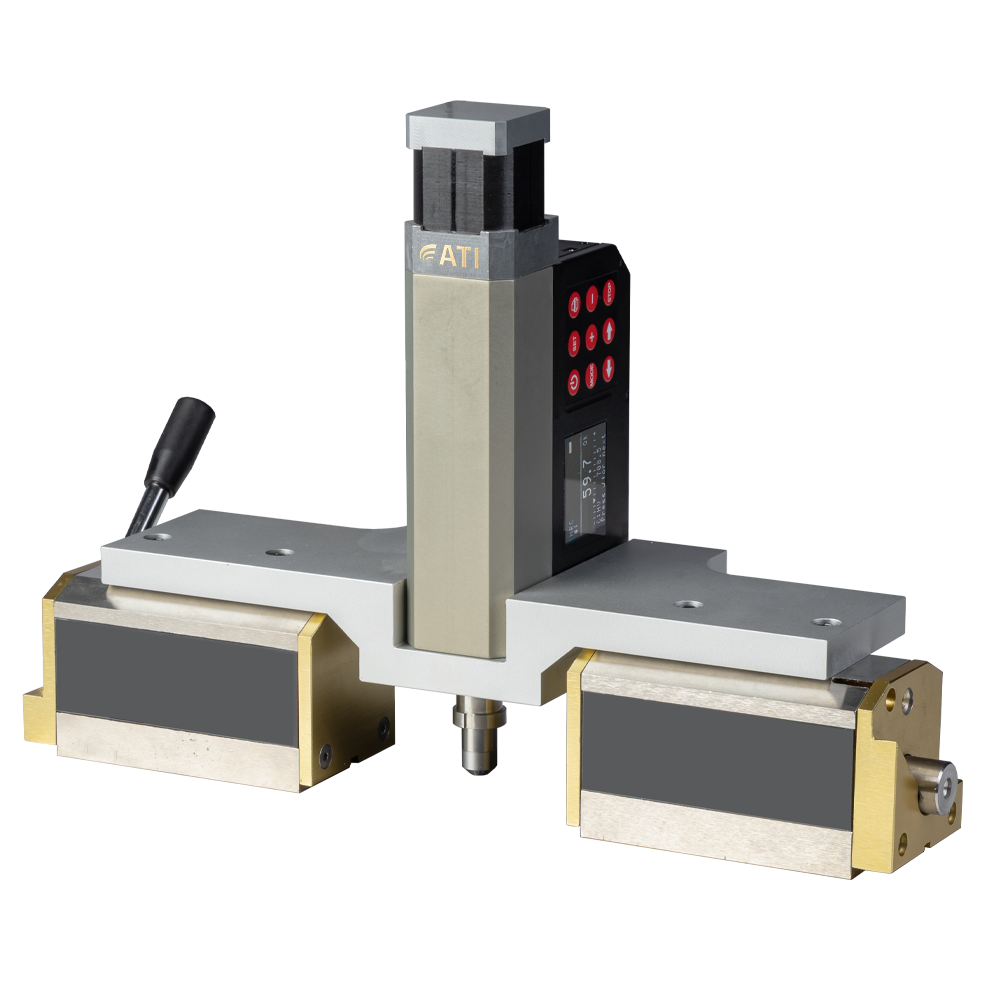

COMPACT SHAPE AND HIGH PRECISION MEASUREMENTS

With a total weight of just 10 kg, including its magnetic base, ATI MAG is engineered for exceptional portability and ease of handling. Its compact dimensions and lightweight design make it ideal for use in diverse testing environments, all while maintaining high precision. The instrument delivers outstanding stability on a variety of surfaces—including cylindrical or elongated components like pipes—thanks to its automatic alignment system. This feature ensures accurate and uninterrupted measurements even under less-than-ideal conditions. Designed for maximum flexibility, ATI MAG can conduct tests in any position, including upside-down orientations, without requiring manual setup changes. This adaptability makes it a perfect fit for numerous testing applications. Offering a powerful combination of accuracy, portability, and intuitive operation, ATI MAG is a dependable solution for professionals across industries where reliable hardness testing is essential. Its ergonomic design and high-performance features make it a go-to instrument for consistent, on-the-go testing.

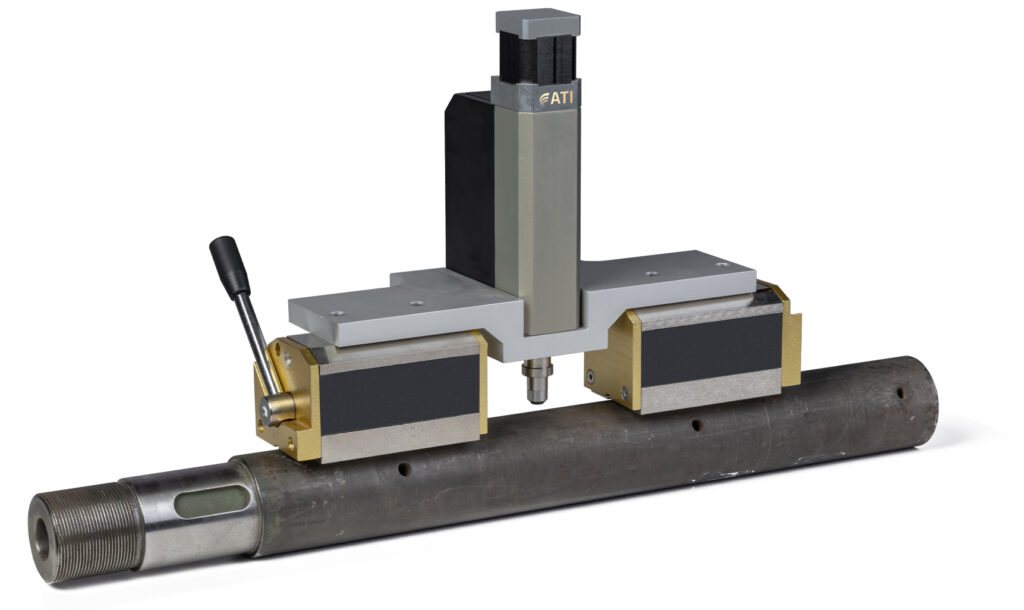

DOUBLE OR SINGLE MAGNETIC CLAMPING BASE

ATI MAG is equipped with a double magnetic clamping system. This clamping system ensures perfect stability during the entire test cycle, and prevents accidental movement in the event of involuntary impacts. This feature enhances performance, providing consistent and accurate results in any conditions. ATI MAG is a portable hardness tester can be used to perform hardness tests on samples of any shape and size.

ATI M70 : double magnetic clamping base for round shape samples of large or small diameters

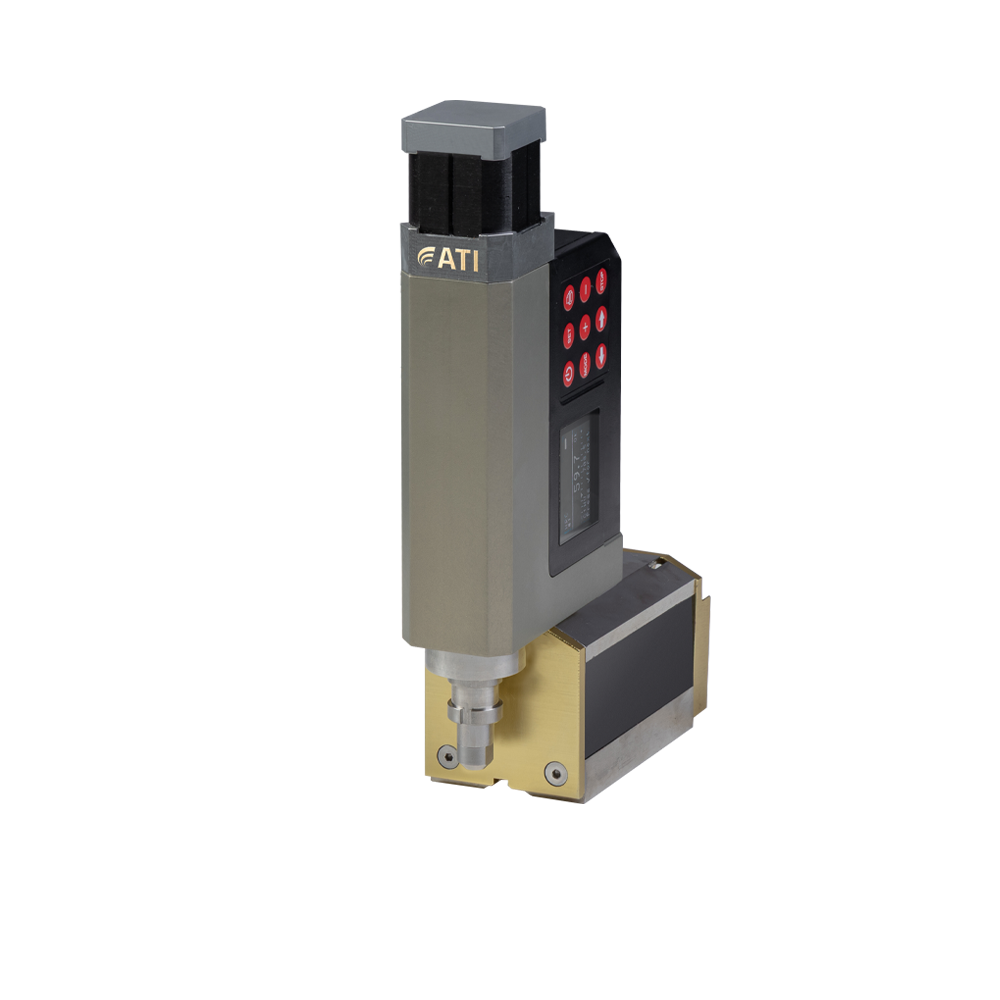

ATI M30 : single magnetic clamping base (300mm) for HR/HB measurements up to 15 mm sample thickness

| Model: | ATI MAG |

| Compliance standards: | ASTM E18, ISO 6508 |

| Preload: | 10 Kg (98.1 N) |

| Rockwell test force: | 60 Kg (588.4 N), 100 Kg (980.7 N), 150 Kg (1471 N) |

| Feasible tests: | HRA, HRB, HRC, HRD, HRF, HRG |

| Accuracy: | 0.0001 mm |

| Resolution: | 0.1 HR |

| Test cycle: | Automatic test cycle with automatic recognition of sample surface |

| Principle of operation: | Load Cell System |

| Data memory: | 100 test results |

| Data output: | USB to PC |

| Printer connection: | Bluetooth to printer |

| Power supply: | Rechargeable Li-ion battery 3000mAh, 3.6V – Work time: 6 hours – Charge time of battery: 2 hours |

| Dimensions: | 200 x 110 x 46 mm |

| Weight: | 2 Kg (10 Kg including the magnet) |

| Magnetic clamping base available : |

ATI M30 : single magnetic clamping base (300mm) for HR/HB measurements up to 15 mm sample thickness ATI M70 : double magnetic clamping base for round shape samples of large or small diameters |