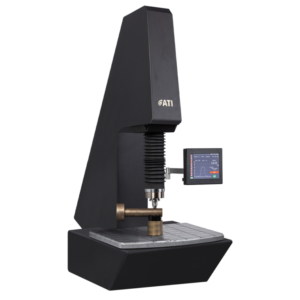

Fully Motorized and Automatic Universal hardness tester

Motorized and Automatic Universal Hardness Tester, complies with ISO 6506, ISO 6507, ISO 6508, ISO 2039-2 and ASTM E10-23, ASTM E103-24, ASTM E384-22, ASTM E92, ASTM E18, ASTM E110 standards. This advanced testing instrument employs a high-precision load cell and Closed-Loop electronic control with a 1 KHz sampling rate, ensuring optimal accuracy and reliability.

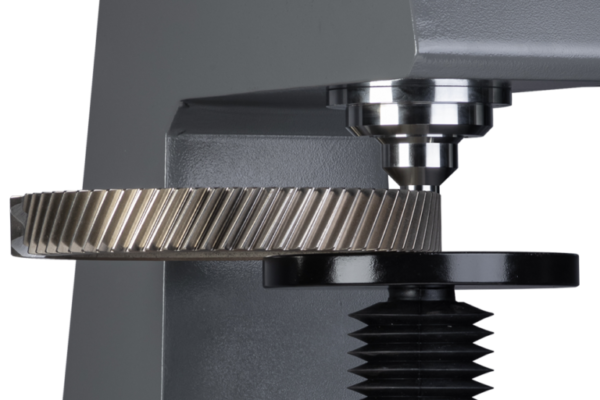

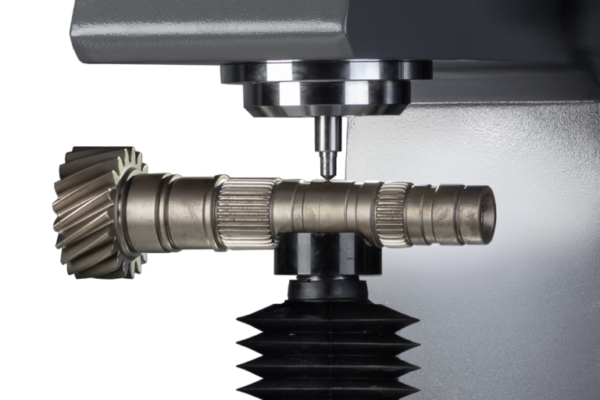

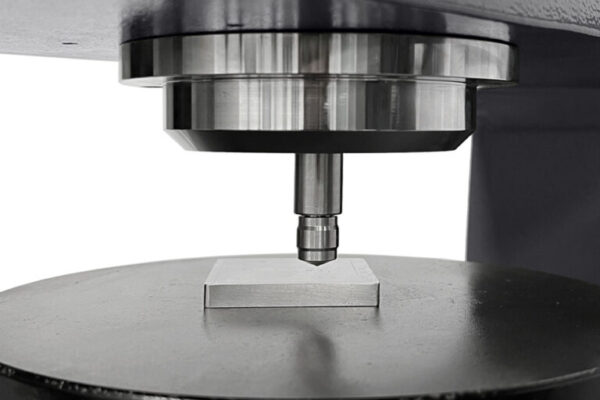

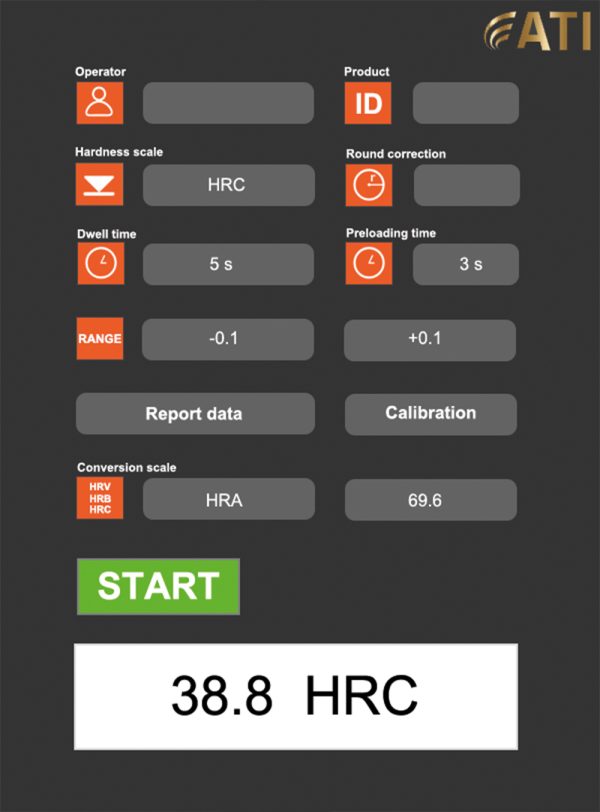

ATI HVBR is a cutting-edge universal hardness tester designed to provide precise hardness measurements of materials through multiple testing methods, including Brinell, Rockwell, and Vickers. Utilizing electronic load cell control, ATI HVBR enhances the accuracy and reliability of measurements. The hardness tester features a large display screen, offering clear visibility and intuitive operation, integrating optical, mechanical, and electrical technologies. This versatile instrument supports testing forces ranging from 1 kg to 250 kg.

Add ATI BR

ATI BR is a digital and portable microscope for Brinell and Vickers indentation reading. The system complies with ISO 6506, ISO 6507, ASTM E10, and ASTM E92 standards. Brinell and Vickers hardness tests can be performed directly on the production line, eliminating the need to move the components. Suitable for parts of any shape or size.

| Model: | ATI HVBR |

| Compliance standards: | SO 6506, ISO 6507, ISO 6508, ISO 2039-2 and ASTM E10-23, ASTM E103-24, ASTM E384-22, ASTM E92, ASTM E18, ASTM E110 |

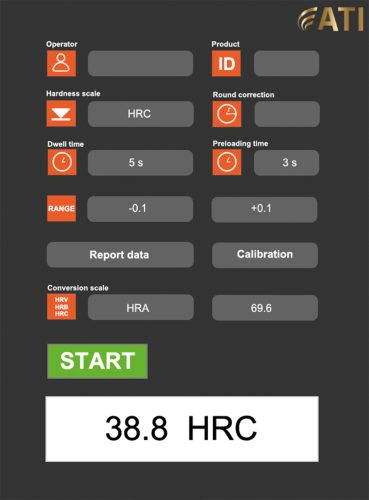

| Hardness scales: | HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HRX, HRS, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, 2.5/62.5 HBWT, 2.5/187.5 HBWT, 5/250 HBWT |

| Conversion scales: | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBW |

| Initial test force: | 3 Kg (29.42 N), 10 Kg (98.07 N) |

| Rockwell test force: | 15 Kg (147.1 N), 30 Kg (294.2 N), 45 Kg (441.3 N), 60 Kg (588.4 N), 100 Kg (980.7 N), 150 Kg (1471 N) |

| Brinell test force: | 1 Kg (9.81 N), 1.25 Kg (12.26 N), 2,5 Kg (24.5 N), 5 Kg (49 N), 6.25 Kg (61.31 N), 10 Kg (98.1 N), 15.62 Kg (153.23 N), 25 Kg (245.25 N), 30 Kg (284.3 N), 31.25 Kg (306.56 N), 62.5 Kg (613 N), 125 Kg (1226.25 N), 187.5 Kg (1839.4 N), 250 Kg (2452 N) |

| Vickers test force: | 1 Kg (9.81 N), 3 Kg (29.41 N), 5 Kg (49.03 N), 10 Kg (98.07 N), 30 Kg (294.2 N), 60 Kg (588.4 N), 100 Kg (980 N) (at request) |

| Dwell time: | Adjustable from 2 to 60 seconds |

| Height capacity: | 290 mm (300mm at request) |

| Depth capacity: | 210 mm |

| Power supply: | 220V-110V , 50 Hz-60 Hz |

| Total dimensions: | 475 x 200 x 700 mm |