Rockwell, Brinell, and Vickers Hardness Testing in One Instrument – Explore a Complete Range of Universal Hardness Testers for All Applications, Industries, and Materials.

Universal Hardness Testers for Comprehensive and Flexible Applications

Discover universal hardness testers designed for unmatched versatility and precision. These machines combine Rockwell, Brinell, Vickers, and more hardness testing methods into one instrument, delivering accurate results for a wide variety of materials and applications across industries.

Materials Tested with Universal Hardness Testers:

- Metals and Alloys: Steel (hardened, stainless, carbon), aluminum, brass, titanium, copper, and cast iron.

- Coatings and Treatments: Surface layers, heat-treated parts, chromium coatings, and nitriding treatments.

- Plastics and Polymers: Thermoplastics, rubber, and composite materials.

- Specialized Materials: Ceramics, carbides, and lightweight alloys.

Parts Suitable for Universal Hardness Testing:

- Incoming Materials: Raw materials, semi-finished goods, heat-treated components, surface-treated parts and components for quality control before production.

- Industrial Components: Gears, pistons, crankshafts, bearings, and rollers.

- Thin Materials and Coatings: Metal sheets, coated surfaces, and microstructures.

- Large and Heavy Parts: Castings, forgings, and structural components.

- Precision Tools and Micro Components: Dies, molds, cutting tools, microelectronics, and medical implants.

- Automotive and Aerospace Parts: Brake rotors, turbine blades, suspension components, and lightweight structural materials.

Why Choose Universal Hardness Testing?

Universal hardness testers provide the flexibility to perform multiple testing methods—Rockwell, Brinell, Vickers, Knoop, and more on a single device. This eliminates the need for multiple machines, saving time and cost while ensuring precise and repeatable results. It’s the perfect solution for laboratories, R&D, quality control, and production lines.

Principles of Universal Hardness Testing:

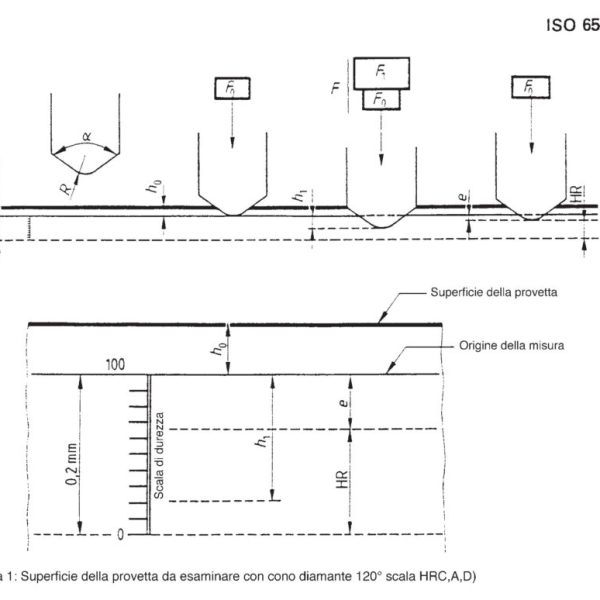

Universal testers allow users to select the desired testing method and indenter, applying controlled loads for accurate measurements. Each method adheres to industry standards for force application and indentation measurement, ensuring compliance and reliability.

Key Features of Our Universal Hardness Testers:

- Flexibility: Perform multiple hardness tests with one machine.

- Precision: High accuracy across Rockwell, Brinell, Vickers, and more scales.

- Ease of Use: Intuitive software for seamless operation and automated processes.

- Durability: Built to withstand demanding industrial and laboratory environments.

Our universal hardness testers are the ultimate solution for diverse testing needs, combining versatility, reliability, and precision. Contact us today to learn more and find the ideal universal hardness tester for your application!

LD250 / LD750

WANT TO LEARN ABOUT THE HARDNESS TESTING PROCEDURE? CLICK HERE!

Simply enough! 1-3000 kgf

Rockwell, Brinell and Vickers

1 to 250 kgf (9,807 to 2452 N) or 3 to 3000 kgf (29.4 to 29421 N)

Testing the hardness of any sample can’t be easier. LD3000AX is an automatic Universal Hardness Tester suitable to test all hardness testing scales.

Universal Hardness Testers by ATI

All-in-One solutions for hardness testing

Universal Hardness Testers: Versatile Solutions for Hardness Testing

Universal hardness testers are advanced machines that combine multiple hardness testing methods—Vickers, Knoop, Brinell, Rockwell, and Superficial Rockwell—in a single, versatile piece of equipment. Designed to handle diverse testing needs, these machines are ideal for laboratories, R&D, and production environments.

ATI’s universal hardness testers stand out for their innovation and quality. Equipped with features like a double tool changer turret (indenter and objective) or an infinite tool changer revolver (indenter, objective, laser, milling, and more), they offer unmatched flexibility and precision.

Customizable and Versatile Universal Hardness Testers

ATI universal hardness testers are available in various configurations:

- Stationary or Portable: Suitable for laboratory or field applications.

- Portal or Radial Designs: Designed to handle unique testing requirements and sample sizes.

- Custom Dimensions: Adaptable to test parts of any size, weight, or geometry.

- Production Line Integration: Seamlessly integrate into automated systems for continuous testing.

Why Choose ATI Universal Hardness Testers?

- Adaptability: Test any material or part, regardless of size, shape, or weight.

- Innovation: Advanced tools like laser alignment and milling for precise measurements.

- High Quality: Built to deliver accurate, repeatable results in demanding applications.

- Custom Solutions: Tailored to meet specific industry requirements.

Discover the unmatched performance and customization of ATI’s universal hardness testers. Explore the full range of features and find the perfect solution for your hardness testing needs. Contact us today to learn more or request a quote!

Hardness Testing: Basic Knowledge

Curious about what a hardness test is and how Rockwell, Brinell, or Vickers tests work? Click the link below to explore detailed explanations and essential information!

Need more assistance? Contact us today—we’re here to help!