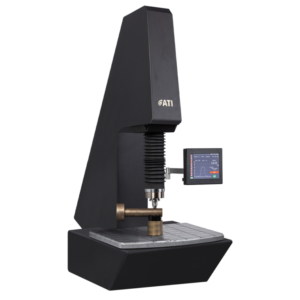

Fully Motorized and Automatic Rockwell and Superficial Rockwell hardness tester

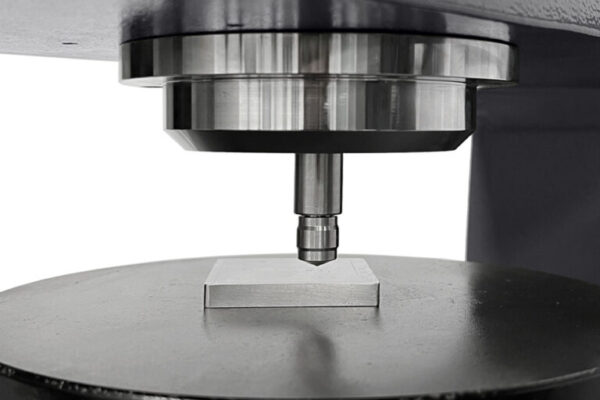

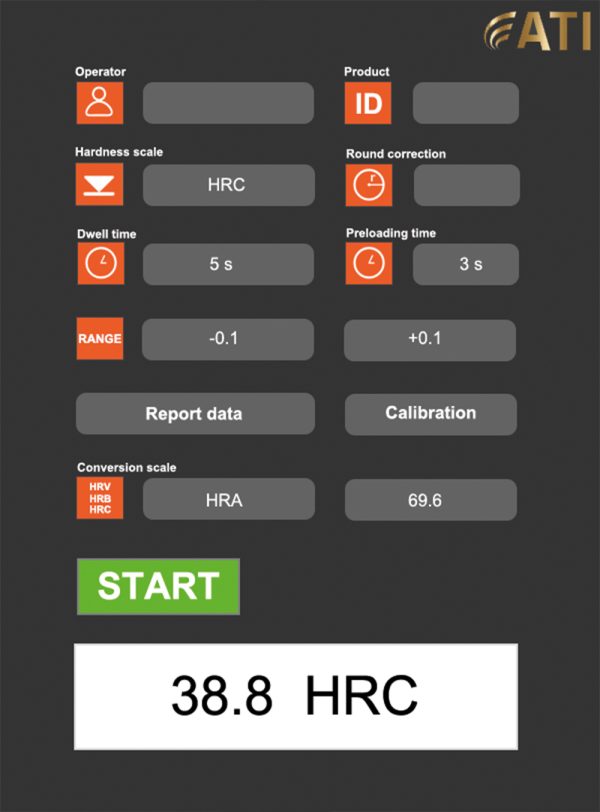

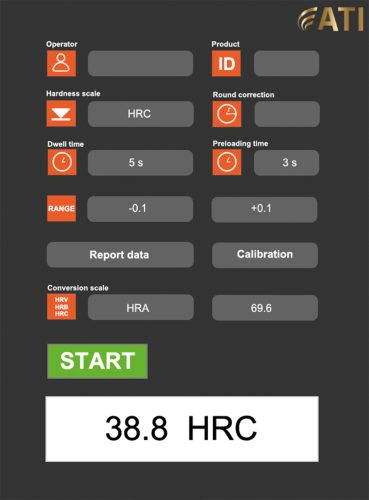

Motorized and Automatic Rockwell and Superficial Rockwell Hardness Tester, engineered to meet the rigorous standards set forth by ASTM E18, ISO 6508, and ISO 2039-2. This advanced testing instrument employs a high-precision load cell and Closed-Loop electronic control with a 1 KHz sampling rate, ensuring optimal accuracy and reliability.

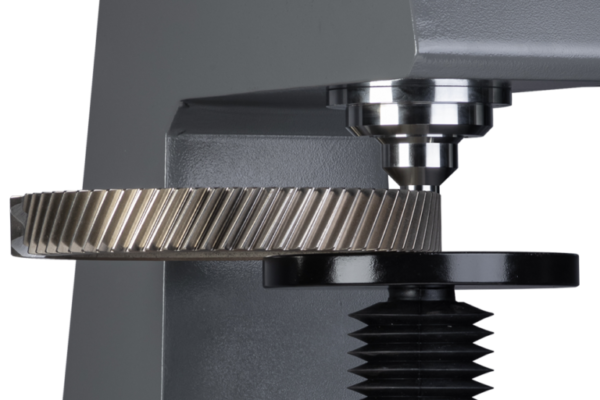

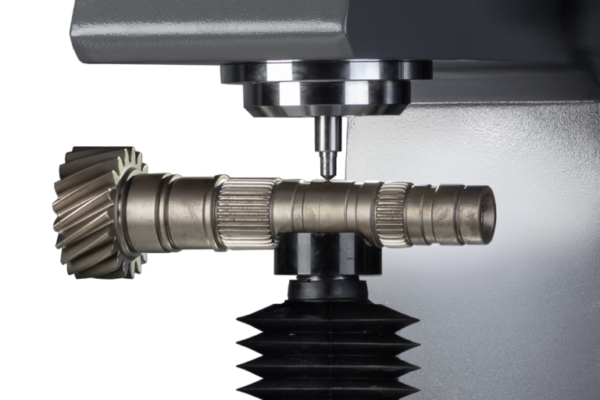

The automatic start test cycle is initiated with a single input command, streamlining the testing process and enhancing efficiency. ATI MRS is designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials. Engineered for high accuracy, this tester meets the needs of manufacturers and engineers who require precise hardness measurements in critical applications.

| Model: | ATI MRS |

| Compliance standards: | ASTM E18, ISO 6508 and ISO 2039-2 |

| Hardness scales: | HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HRN, HRT, HRX, HRS, ISO 2039-2 |

| Conversion scales: | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS,HBW |

| Initial test force: | 3 Kg (29.42 N), 10 Kg (98.07 N) |

| Total test force: | 15 Kg (147.1 N), 30 Kg (294.2 N), 45 Kg (441.3 N), 60 Kg (588.4 N), 100 Kg (980.7 N), 150 Kg (1471 N) |

| Brinell test force: | 62.5 Kg (613N), 125 Kg (1226.2 N), 187.5 Kg (1839.4 N) (at request) |

| Dwell time: | Adjustable from 2 to 60 seconds |

| Max height of test piece: | 230 mm (300mm at request) |

| Depth capacity of throat: | 170 mm |

| Power supply: | 220V / 110V , 50 Hz / 60 Hz |

| Total dimensions: | 475 x 200 x 700 mm |