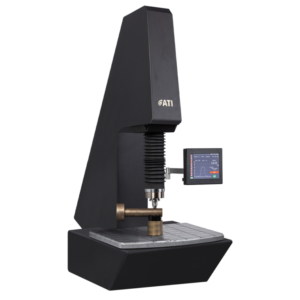

Automatic bench Rockwell and Superficial Rockwell hardness tester with Brinell and Vickers additional scales

The ATI R / RS Rockwell hardness tester is a high-precision, bench instrument developed for automated hardness testing in industrial quality control and laboratory environments. Designed to support multiple hardness testing methods on a single platform, the ATI R / RS combines electronic force control, digital depth measurement, and intuitive operation to deliver consistent and repeatable results. This hardness tester is ideal for manufacturers and laboratories that require reliable compliance with international testing standards while maintaining efficiency and ease of use in daily testing operations.

Available Hardness Test Scales

| Rockwell Hardness Scales: | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV |

| Superficial Rockwell Hardness Scales (15–30–45): | HRN, HRT, HRW, HRX, HRY |

| Brinell HBW Hardness Scales (Optional): | 1/1, 1/1.25, 1/2.5, 1/5, 1/10, 1/30 2.5/6.25, 2.5/15.62, 2.5/31.25, 2.5/62.5, 2.5/187.5 5/25, 5/31.25, 5/62.5, 5/125, 5/250 |

| Brinell HBWT Hardness Scales – Depth Measurement (Optional): | 2.5/62.5, 2.5/187.5, 5/250 |

| Vickers Hardness Scales (Optional): | HV1, HV2, HV3, HV5, HV10, HV20, HV30, HV50, HV100 |

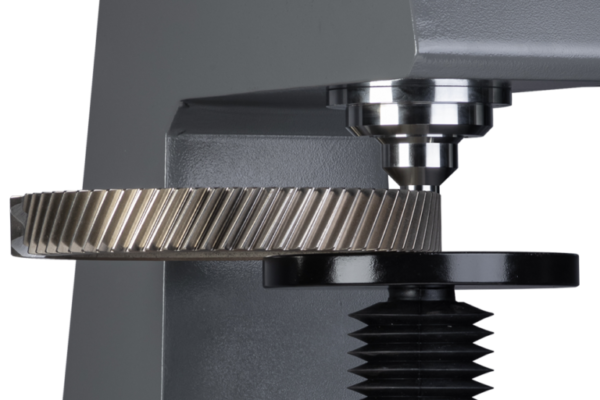

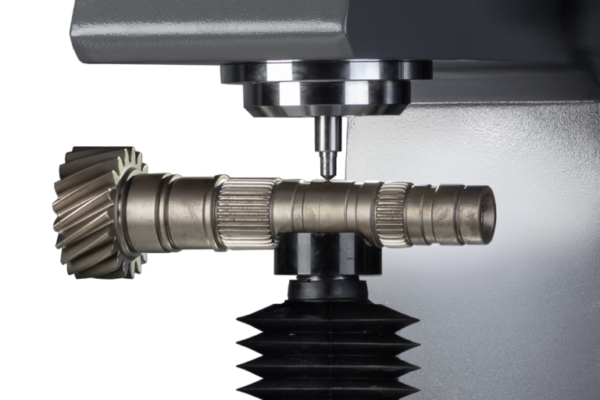

Measurable materials and applications

| Rockwell | Suitable for medium to thick metal components where fast and repeatable hardness measurements are required. Typical materials: carbon steel, alloy steel, stainless steel, tool steel, cast iron, copper, brass, bronze, aluminum alloys, nickel alloys. Typical applications: heat-treated steel parts, machined components, shafts, gears, forgings, incoming material inspection, production quality control. |

| Superficial Rockwell | Designed for thin materials, surface-hardened parts, and coatings where standard Rockwell loads could cause excessive penetration. Typical materials: thin steel sheets, hardened surface layers, carburized and nitrided components, plated parts, coated metals, light alloys. Typical applications: thin metal sheets, small precision parts, surface-treated components, quality control of coatings and shallow hardened layers. |

| Brinell Hardness Scales – HBWT (Depth Measurement) |

Ideal for testing softer metals and large components using depth measurement without optical evaluation. Typical materials: low-carbon steel, aluminum alloys, copper alloys, brass, bronze, soft cast iron. Typical applications: castings, forgings, bars, billets, structural components, production environments requiring fast and robust hardness testing. |

| Brinell Hardness Scales – HBW (Optical Measurement) |

Used for materials with coarse or heterogeneous microstructures where a larger indentation provides representative hardness values. Typical materials: cast iron, aluminum alloys, copper alloys, brass, bronze, non-ferrous metals. Typical applications: foundry products, large machined parts, raw materials inspection, metallurgical laboratories. |

| Vickers Hardness Scales | Suitable for a wide range of materials, from very soft to very hard, including small parts and thin sections when used with low test forces. Typical materials: hardened steel, stainless steel, non-ferrous metals, hard alloys, coatings, technical materials. Typical applications: laboratory testing, research and development, thin sections, small components, coating evaluation, failure analysis. |

Mechanical & Technical Specifications:

| Maximum Workpiece Height: | 270 mm |

| Throat Depth (Column to Indenter): | 210 mm |

| Dimensions (L x W x H): | 475 x 200 x 700 mm |

| Weight: | 70 kg |

| Power Supply: | AC 110V, 220V ±5%, 50~60Hz |

| Dwell Time: | Adjustable from 2 to 60 seconds |

How to do a Rockwell Hardness Test

Performing a Rockwell hardness test with the ATI RS hardness tester is fast and fully automated. The operator only needs to:

- Place the sample securely on the anvil

- Press the START button

- Wait for the hardness test result to be displayed

During the test, the motorized hardness tester automatically performs all phases of the Rockwell method: application of the preliminary test force, application of the main test force, controlled dwell time, release of the main force, and final depth measurement under the recovery force.

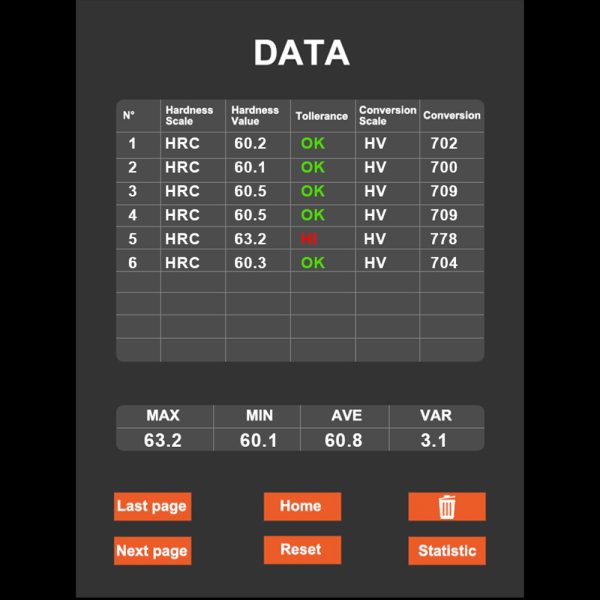

The measured Rockwell hardness value is shown clearly on the display and highlighted in green or red according to the preset tolerance limits, allowing immediate pass/fail evaluation for quality control and production environments.

How to do a Brinell or Vickers Hardness Test

Performing a Brinell hardness test or a Vickers hardness test with the ATI RS hardness tester is as simple as it is for Rockwell testing.

Brinell Hardness Test – HBWT (Depth Measurement)

In accordance with ASTM E103, the ATI RS measures the depth of indentation directly during the test cycle. After pressing the START button, the hardness value is calculated automatically and displayed on the screen.

Brinell HBW and Vickers Hardness Test – Optical Measurement

For Brinell HBW and Vickers hardness testing, the ATI RS performs a precise and controlled indentation on the test surface. To obtain the final hardness value, the operator measures the indentation using an external microscope, either manual or digital, and calculates the result according to the applicable standards.

Hardness Tester Main Features

Clamping System

The integrated clamping system ensures maximum stability throughout the entire hardness test, even on long or unstable samples. The open clamping hood keeps the indenter and test area fully visible for safe and accurate operation.

Ergonomics & Usability

Ergonomic hardness tester frame with increased height for improved operator comfort. The open design provides a clear, unobstructed view of the specimen and eliminates the need to drill the bench table for the elevating screw.

Touchscreen Control Panel

Modern touchscreen control panel with 120° rotation and retractable articulated arm for flexible positioning. The side-mounted design allows easy adjustment for optimal visibility and can be moved out of the way to create additional workspace when testing large components.

Software test settings

Fast and easy operation, with specimen and operator ID input. Automatic hardness correction compensates for convex cylindrical surfaces. Color-coded pass/fail results (OK/NOK) are displayed based on preset tolerances. Dark mode improves visibility and comfort.

Live hardness measurement

During testing, the complete hardness test cycle can be monitored in real time, with load-time diagrams, countdown for each loading phase, live indenter movement visualization, and clear indication of test force and indenter type.

Hardness results report

Clear test data reports showing each result with color-coded pass/fail status (OK/NOK) and converted values. Results can be edited or cleared, statistical data is available, and reports can be exported as TXT files via USB.