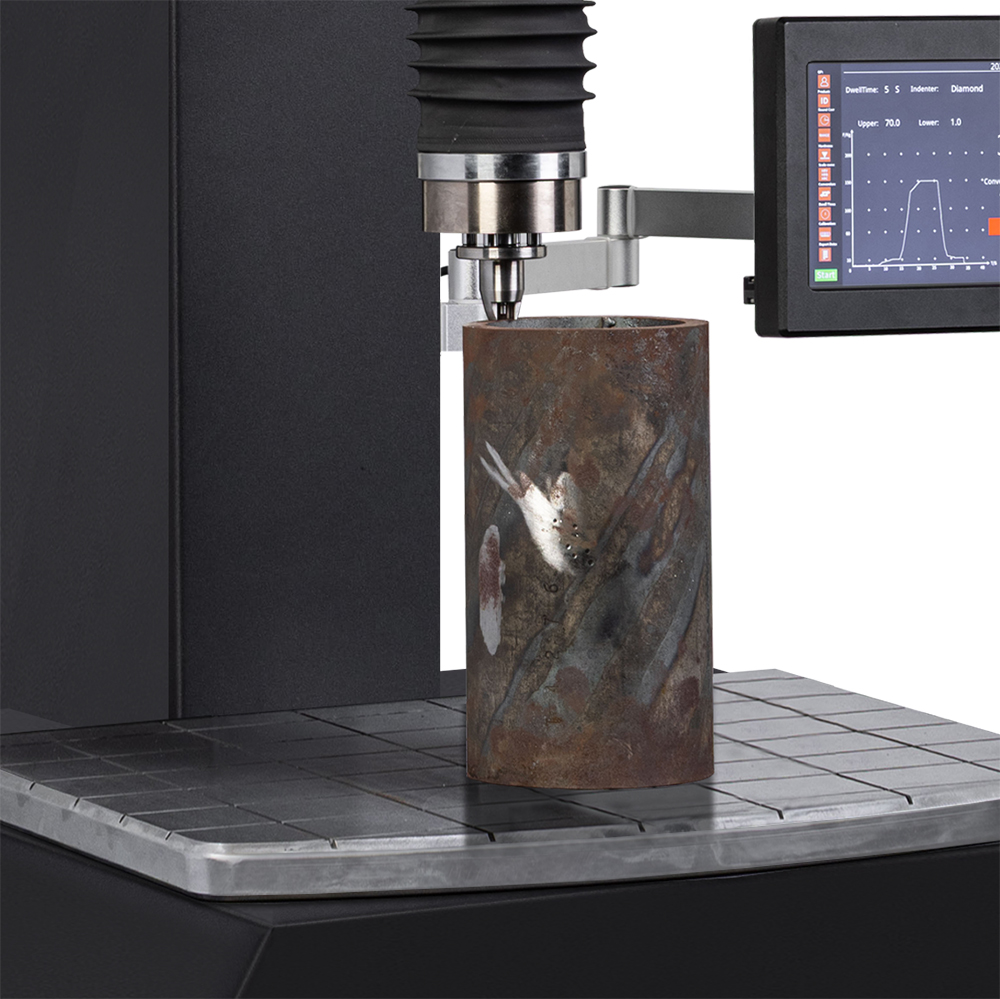

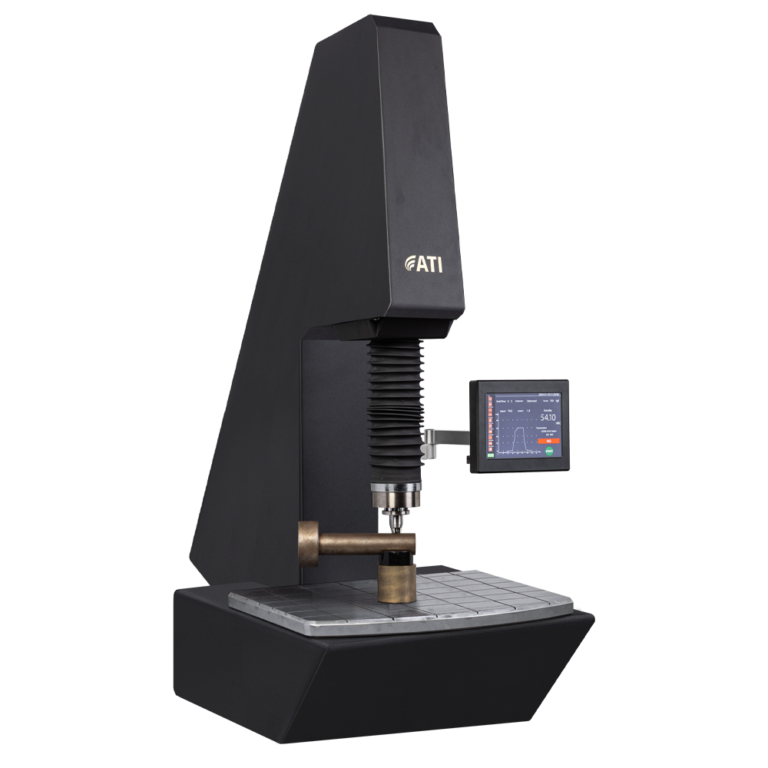

Automatic Rockwell hardness tester.

ATI HTR is a fully automatic advanced Rockwell hardness tester designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Test force closed-loop control system ensures precise automatic tracking and testing, eliminating any poten- tial errors caused by deformation of the frame or workpiece.

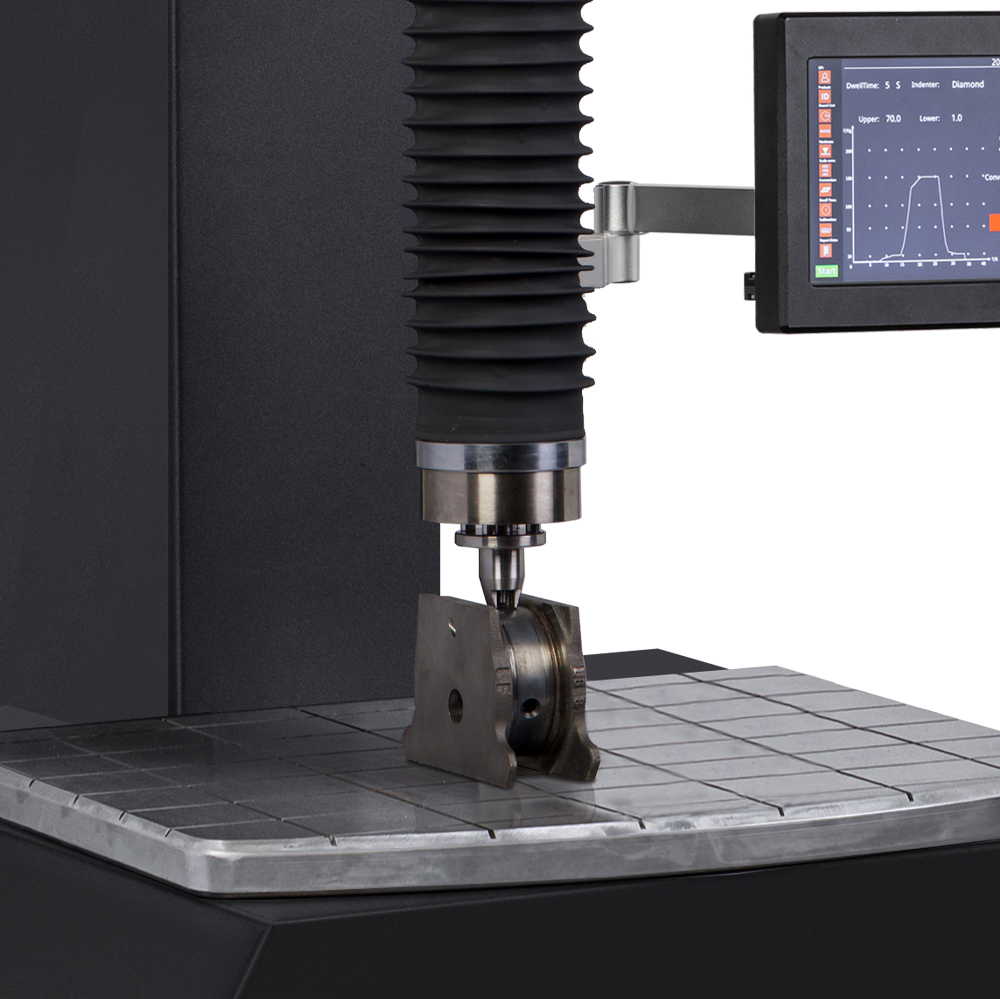

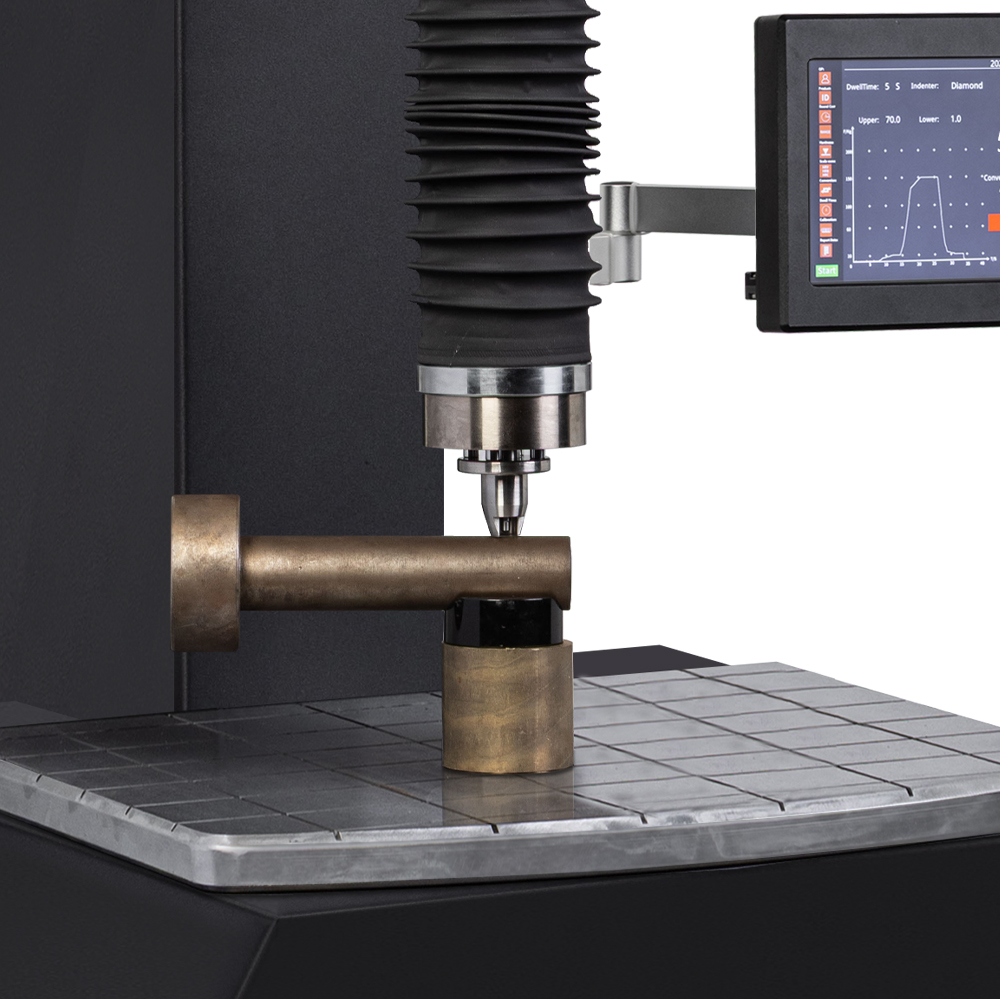

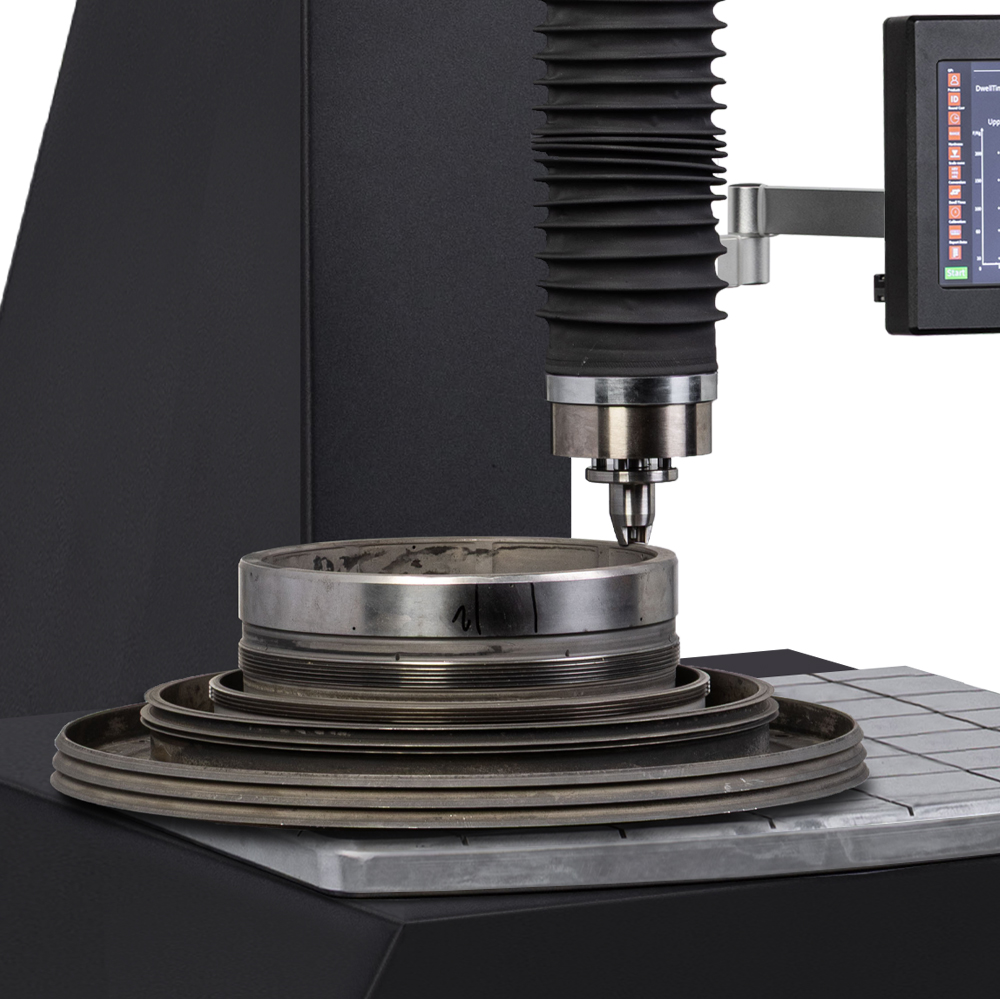

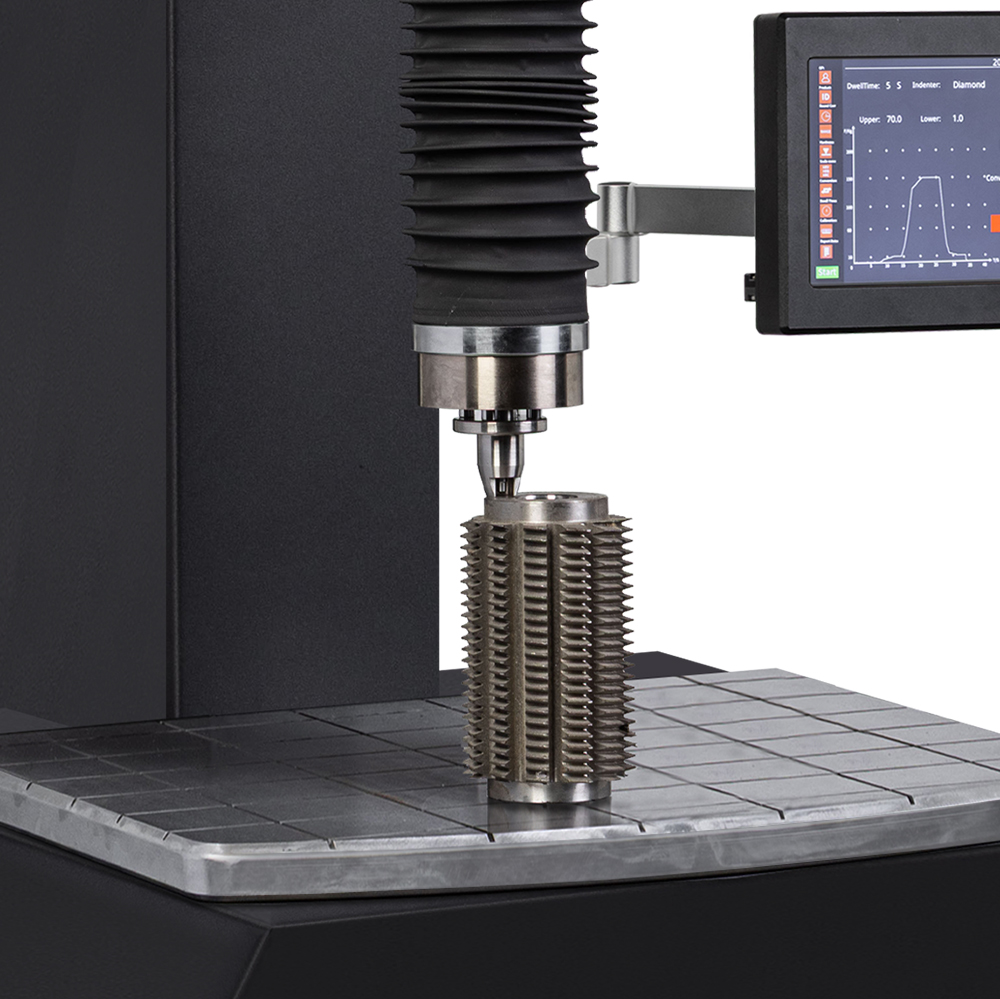

The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force.

Our advanced test force closed-loop control system ensures precise automatic tracking and testing, eliminating any potential errors caused by deformation of the frame or workpiece. This system is designed to optimize efficiency and accuracy in testing processes, featuring a high-precision optical grating displacement measuring system. The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force. This enhances both operator convenience and repeatability in testing procedures, especially when working with irregularly shaped or heavy workpieces. Our equipment includes a large test table, ideal for accommodating workpieces of various shapes and sizes, even those considered abnormal or oversized. The user-friendly large LCD display with menu based operation ensures intuitive navigation through its comprehensive set of functions, such as data processing and hardness conversion across different scales. Additionally, the system is equipped with a bluetooth data interface for seamless communication and comes with a printer for immediate result output. For more advanced operations, there is an optional upper computer package that includes specialized software to further enhance data management and analysis. The system’s precision conforms to rigorous international standards, including ISO 6508 , ASTM E18, and GB/T 230.2. This solution is ideal for manufacturers seeking a highly ac- curate, fully automated hardness testing system that minimizes human error while maximizing productivity and data accuracy.

| Model: | ATI HTR |

|

Compliance standards: |

ISO 6508 , ASTM E18, and GB/T 230.2 |

|

Hardness scales: |

HRA, HRB, HRC, HRD,HRE,HRF, HRG,HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y |

| Measuring range: | 20-95HRA,,10-100HRB,,10-70HRC,,70-94HR15N, 42-86HR30N, 20-77HR45N, 67-93HR15TW, 29-82HR30TW, 10-72HR45TW |

| Pre-load: | 29.4 N (3 kgf), 98.1 N (10 kgf) |

| Total test force: | 147.1 N (15 kgf), 294.2 N(30 kgf), 441.3N(45kgf), 588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf) |

| Resolution: | 0.01 HR |

| Max height of test piece: | 170 mm (can be customized,max 350 mm) |

| Depth capacity of throat: | 200 mm |

| Power supply: | 220V / 110V , 50 Hz / 60 Hz |

| Total dimensions: | 669 x 477 x 877 mm – Weight: 130 Kg |